📑 HDPE vs LDPE Plastic Bags: Key Differences, Applications, and Advantages

When it comes to plastic packaging, HDPE (High-Density Polyethylene) and LDPE (Low-Density Polyethylene) are the two most common types of materials used to manufacture plastic bags. While both are polyethylene-based, their properties, applications, and advantages differ significantly. In this article, we’ll explore the differences between HDPE and LDPE plastic bags, helping businesses and consumers choose the right option for their specific needs.

🔍 What is HDPE Plastic?

HDPE (High-Density Polyethylene) is a thermoplastic made from petroleum. It has a high strength-to-density ratio and a tightly packed molecular structure, making it more rigid, stronger, and resistant to impact than other types of polyethylene.

Key properties of HDPE plastic bags:

High tensile strength

Stiff and durable

Excellent moisture and chemical resistance

Lightweight yet strong

Slightly opaque appearance

Noisy (crinkly) texture when handled

Common applications:

Grocery bags

Trash liners

Food packaging bags

Industrial packaging

Retail shopping bags

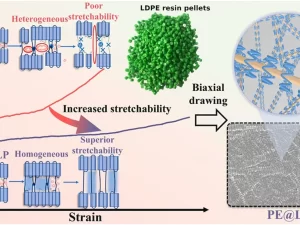

🔍 What is LDPE Plastic?

LDPE (Low-Density Polyethylene) is another thermoplastic derived from petroleum but with a looser molecular structure. This gives it a softer, more flexible texture, and it is often used where softness, transparency, and elasticity are preferred.

Key properties of LDPE plastic bags:

Low tensile strength but highly flexible

Soft and smooth texture

Transparent or semi-transparent

Good moisture barrier

Resistant to chemicals and impacts

Less crinkly than HDPE

Common applications:

Ziplock bags

Bread bags

Produce bags

Garment bags

Packaging for lightweight products

📊 HDPE vs LDPE: A Quick Comparison Table

| Feature | HDPE Plastic Bags | LDPE Plastic Bags |

|---|---|---|

| Density | High | Low |

| Strength | High | Medium |

| Flexibility | Low | High |

| Transparency | Opaque or semi-transparent | Clear or semi-clear |

| Texture | Stiff, crinkly | Soft, smooth |

| Moisture Resistance | Excellent | Good |

| Common Uses | Grocery, trash, industrial | Food, garment, packaging |

🌿 Which is More Eco-Friendly: HDPE or LDPE?

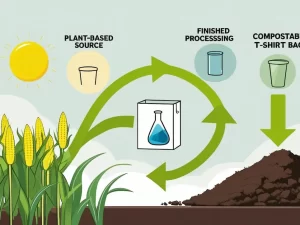

Both HDPE and LDPE are recyclable materials. However:

HDPE bags are typically easier to recycle due to their denser structure.

LDPE bags may require specialized recycling processes depending on local facilities.

Additionally, manufacturers are increasingly developing recycled HDPE and LDPE plastic bags to reduce environmental impact and promote circular production.

✅ Conclusion

HDPE and LDPE plastic bags both serve essential roles in various industries, from retail to food service and waste management. By understanding their key differences in strength, flexibility, and applications, businesses can select the most suitable option for their packaging needs.

For those looking for sustainable plastic bag solutions, considering recycled HDPE packaging and biodegradable alternatives is a growing trend in the packaging industry.