📖 Properties of HDPE Bags: Why They Dominate the Packaging Industry

High-Density Polyethylene (HDPE) bags are one of the most widely used types of plastic bags in the global packaging market. Known for their durability, versatility, and cost-efficiency, HDPE plastic bags play a vital role in retail, food service, waste management, and industrial applications. In this article, we’ll explore the properties of HDPE bags, compare them with other materials, and examine their growing role in sustainable packaging solutions.

What is High-Density Polyethylene (HDPE)?

HDPE is a thermoplastic polymer made from the monomer ethylene. It’s categorized as a polyethylene variant with a high strength-to-density ratio. HDPE film is lightweight yet exceptionally strong, making it ideal for producing shopping bags, garbage liners, packaging films, and industrial wraps.

Key Properties of HDPE Bags

| Property | Description |

|---|---|

| Density | 0.93–0.97 g/cm³, higher than LDPE, giving it greater strength |

| Tensile Strength | Excellent resistance to stretching and tearing |

| Moisture Barrier | Low moisture permeability, ideal for food and retail packaging |

| Chemical Resistance | High resistance to acids, bases, and many solvents |

| Temperature Tolerance | Withstands temperatures from -50°C to 110°C |

| Lightweight | Despite being thin, maintains strong durability |

| Transparency | Typically translucent to opaque, but can be customized |

| Recyclability | Fully recyclable under recycling code #2 |

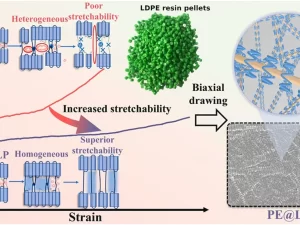

HDPE vs. LDPE Plastic Bags

While both HDPE and LDPE (Low-Density Polyethylene) bags are made from polyethylene, they differ in structure and performance:

| Feature | HDPE Bags | LDPE Bags |

|---|---|---|

| Density | High (0.93–0.97 g/cm³) | Low (0.91–0.93 g/cm³) |

| Strength | Stronger, more rigid | Softer, more flexible |

| Clarity | Less transparent | More transparent |

| Cost | Generally lower | Slightly higher |

| Use Cases | Grocery bags, waste bags, shipping | Food wraps, ziplock bags, soft bags |

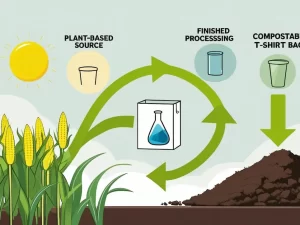

Recycled and Sustainable HDPE Bags

With growing demand for eco-friendly packaging, many manufacturers are now producing recycled HDPE packaging and sustainable HDPE bags. These are made from post-consumer recycled (PCR) materials or bio-based HDPE resins, offering a lower environmental footprint while retaining key performance properties.

Benefits include:

Reduced energy and resource consumption during production

Lower greenhouse gas emissions

Contribution to a circular economy

Conclusion

HDPE bags remain an essential component in modern packaging thanks to their outstanding physical properties, affordability, and versatility. With advances in recycling and sustainable manufacturing practices, HDPE plastic bags are evolving into more eco-friendly options without compromising performance. Whether for food, retail, waste management, or industrial applications, High-Density Polyethylene film continues to deliver reliable, efficient, and increasingly sustainable packaging solutions.