📖 What is PE (Polyethylene)? An Overview of Its Properties, Types, and Applications

Introduction to Polyethylene (PE)

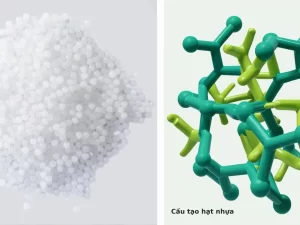

Polyethylene (PE) is the most widely produced plastic in the world. It belongs to the family of polyolefin resins and is known for its excellent versatility, durability, and cost-effectiveness. PE is a thermoplastic polymer made by polymerizing ethylene monomers, creating long hydrocarbon chains that form flexible and tough materials.

This plastic is used extensively in packaging, construction, agriculture, automotive, and consumer goods.

Properties of Polyethylene (PE)

Polyethylene materials offer a wide range of physical and chemical properties depending on their density and molecular structure:

Lightweight and Flexible

High Impact Resistance

Excellent Chemical Resistance

Good Electrical Insulation Properties

Waterproof and Moisture Resistant

Recyclable and Thermoformable

Types of Polyethylene (PE)

There are several types of polyethylene, categorized based on density and branching structure:

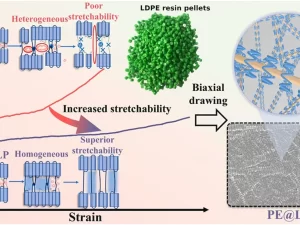

1️⃣ LDPE (Low-Density Polyethylene)

Soft, flexible, and transparent

Used for plastic bags, film wrap, squeeze bottles, and agricultural films

- Enhancing the biodegradation of low-density polyethylene (LDPE) using novel bacterial consortia: Bacillus sp. AS3 and Sphingobacterium sp. AS8

2️⃣ HDPE (High-Density Polyethylene)

Strong, rigid, and opaque

Used for grocery bags, rigid containers, pipes, bottle caps, and waste bins

- Transforming high-density polyethylene plastic bags into eco-friendly carbon dots for detecting ferric (Fe3+) ions

3️⃣ LLDPE (Linear Low-Density Polyethylene)

Combines flexibility of LDPE with enhanced strength

Used for stretch films, packaging films, and trash bags

4️⃣ MDPE (Medium-Density Polyethylene)

Tougher than LDPE, softer than HDPE

Used for gas pipes, shrink film, and carrier bags

PE Plastic Bag Applications

PE is extensively used to manufacture various types of plastic bags due to its outstanding flexibility and affordability. Common applications include:

Food packaging films

Agricultural greenhouse covers

Industrial liners and protective films

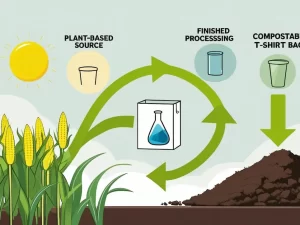

Environmental Considerations

While PE is fully recyclable, improper disposal contributes to plastic waste pollution. Advances in biodegradable PE alternatives and recycled PE products are gradually reducing the environmental impact of traditional polyethylene plastics.

Conclusion

Polyethylene is a highly adaptable material used across multiple industries. Its variations — LDPE, HDPE, LLDPE, and MDPE — offer a balance of flexibility, strength, and cost, making PE indispensable in modern manufacturing and packaging solutions.