LDPE vs. HDPE: Choosing the Right Polyethylene and Hanoi Plastic Bag’s Innovation

In today’s interconnected world, plastics are indispensable, shaping everything from essential packaging to advanced industrial components. Among the vast array of polymer materials, Polyethylene (PE) stands out as a foundational pillar, with its two primary forms – Low-Density Polyethylene (LDPE) and High-Density Polyethylene (HDPE) – dominating various applications. While both are derived from ethylene, their distinct molecular structures endow them with unique characteristics, making the choice between them dependent entirely on specific project requirements.

This article will delve into the fundamental differences between LDPE and HDPE, dissecting their properties, production methods, and applications. Crucially, we will highlight how Hanoi Plastic Bag, a leading innovator in Vietnam’s plastics industry, leverages its deep material science expertise and groundbreaking research to optimize both LDPE and HDPE, providing high-performance, tailored solutions for a sustainable future.

1. Understanding Polyethylene’s Diverse Forms

1.1. Low-Density Polyethylene (LDPE): The Flexible and Versatile Choice

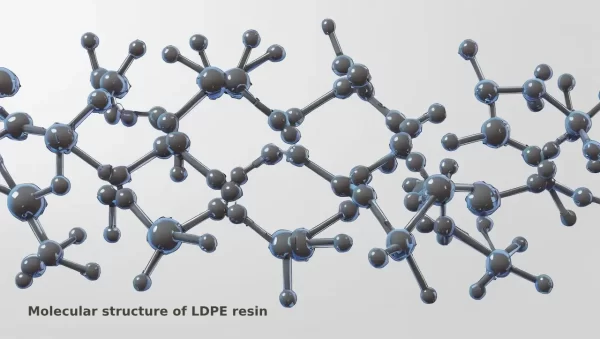

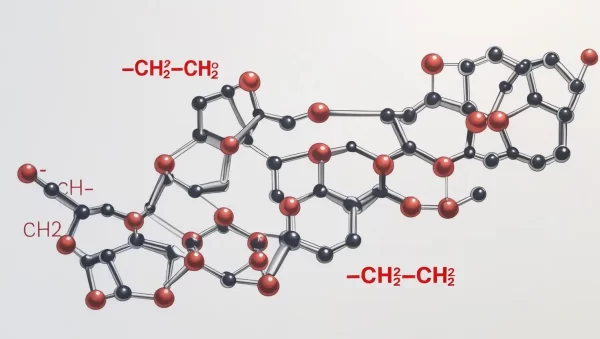

LDPE is a thermoplastic characterized by a highly branched molecular structure. These numerous side branches prevent the polymer chains from packing tightly together, resulting in a lower density and a material that is notably more flexible and pliable than HDPE.

- Key Physical Properties: LDPE typically has a density ranging from 0.910 to 0.940 g/cm³. It possesses a lower melting point, generally around 105 to 115°C (221 to 239°F), making it easily moldable and processable. Its high flexibility is maintained even at low temperatures, allowing it to be bent, stretched, and folded without breaking. While not fully transparent, it exhibits a slightly cloudy appearance, allowing some light transmission. LDPE has lower tensile strength but boasts excellent impact resistance, meaning it can absorb sudden shocks without cracking.

- Chemical Resistance: LDPE shows good resistance to acids and bases, though it is less resilient to solvents and organic chemicals, susceptible to swelling or softening upon exposure.

- Production Method: LDPE is typically produced through free-radical polymerization under high pressure and temperature, where an initiator (often a peroxide compound) facilitates the branching of ethylene molecules.

- Common Applications: Its flexibility and excellent resistance to moisture and chemicals make LDPE ideal for plastic bags (shopping bags, garbage bags), shrink wraps, squeeze bottles, agricultural films, and various food packaging films.

1.2. High-Density Polyethylene (HDPE): The Rigid and Robust Solution

HDPE is a thermoplastic characterized by a more linear molecular structure with minimal branching. This allows its molecules to pack together densely, yielding a material with higher density, increased rigidity, and superior strength.

- Key Physical Properties: HDPE has a higher density, typically ranging from 0.941 to 0.965 g/cm³. Its melting point is significantly higher, usually around 120 to 160°C (248 to 320°F), making it highly resistant to heat deformation. HDPE is less flexible than LDPE, maintaining its shape and rigidity under stress. It is opaque, effectively blocking light transmission, which also contributes to better UV resistance. HDPE exhibits higher tensile strength, making it stronger and more resistant to stretching and tearing, along with good impact resistance.

- Chemical Resistance: HDPE excels in chemical resistance, exhibiting excellent resilience to a wide range of chemicals, including acids, bases, alcohols, and various organic solvents. It is also highly resistant to oil and grease.

- Production Method: HDPE is primarily synthesized through Ziegler-Natta polymerization or coordination polymerization, using specialized catalysts that promote the formation of long, linear polymer chains. This process occurs at higher temperatures and pressures compared to LDPE.

- Common Applications: Its strength, rigidity, and chemical resistance make HDPE suitable for durable products like pipes, containers (e.g., milk jugs, detergent bottles), plastic lumber, automotive fuel tanks, and protective linings.

2. Key Differentiating Factors: A Detailed Comparison

The core differences between LDPE and HDPE stem directly from their molecular structures and the polymerization processes used to create them:

3. Recyclability and Environmental Considerations

Both LDPE and HDPE are recyclable, contributing to waste reduction and resource conservation. However, their recycling processes and rates differ:

- Recycling Codes: LDPE is assigned the recycling code “4“, while HDPE is code “2“. These codes facilitate proper sorting in recycling streams.

- Recycling Process & Rate: HDPE generally boasts a higher recycling rate due to its greater density and ease of processing, making it more economically viable to collect and reprocess. It is commonly shredded, melted, and reformed into new products. LDPE recycling, while possible, has a lower rate because its lower density makes collection and reprocessing less economically attractive, often requiring more energy and effort.

- Environmental Impact: From a recycling perspective, HDPE’s higher recyclability and lower energy requirements in processing make it generally more sustainable in its end-of-life management compared to LDPE, contributing more significantly to reducing plastic waste and conserving resources.

4. Hanoi Plastic Bag’s Strategic Mastery: Optimizing Both PE Types

Hanoi Plastic Bag stands out as a company that doesn’t just utilize these ubiquitous polymers, but actively drives innovation in their development and application to create high-performance, sustainable plastic solutions for diverse needs in Vietnam and globally. Their deep understanding of polymer science allows them to unlock the full potential of both HDPE and LDPE.

4.1. Advancing HDPE: The Biaxial Orientation Breakthrough

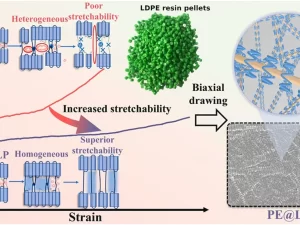

Hanoi Plastic Bag has made groundbreaking strides in enhancing HDPE’s capabilities through advanced research in Biaxially Oriented HDPE (BOHDPE) via precise amorphous control. Recognizing HDPE’s inherent stiffness and fast crystallization rate as limitations for biaxial stretching, their team focused on manipulating the non-crystalline (amorphous) regions of the polymer.

- Key Research Findings: Through meticulous studies using techniques like positron annihilation lifetime spectroscopy (PALS) and dynamic mechanical analysis (DMA), their research revealed that a minor addition of liquid paraffin (LP) (1-3% content) fundamentally changes the amorphous structure of HDPE. LP resides within the amorphous region, effectively reducing free volume pores (from ~4% to 2.2%) and activating the β relaxation of stress transmitters. This mechanism initiates homogeneous yielding and significantly accelerates molecular disentanglement under strain, dramatically improving stretchability.

- Cavitation Suppression: A critical breakthrough was the discovery that LP can completely suppress cavitation (defect formation during stretching) at just 2% content, proving that cavitation is caused by the coalescence of free volume pores.

- Unprecedented Performance: This leads to a remarkable increase in maximal biaxial draw ratio: from 3×3 for pristine HDPE to an astounding 7×7 for HDPE with 3% LP. This enables Hanoi Plastic Bag to produce BOHDPE films with superior mechanical properties, allowing for significantly thinner, yet stronger, films. This innovation directly supports the “Reduce, Reuse, and Recycle” mandate, facilitating single-material packaging that is more recyclable and requires fewer virgin resources.

4.2. Refining LDPE: Tailored Solutions for Flexible Packaging

Concurrently, Hanoi Plastic Bag applies its extensive expertise to LDPE production, specializing in optimizing its use for a wide array of flexible packaging applications. Recognizing LDPE’s unparalleled flexibility, toughness, and excellent heat-sealing properties, they focus on:

- Optimized Film Solutions: Manufacturing high-quality plastic bags, shopping bags, garbage bags, and packaging films that leverage LDPE’s elasticity and impact resistance for specific end-use requirements.

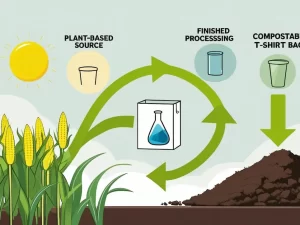

- Sustainability Integration: Their commitment extends beyond basic manufacturing to continuous improvement in sustainability. This includes rigorous quality control to ensure product reliability and actively exploring advanced techniques for incorporating higher percentages of recycled content into their LDPE films without compromising essential performance characteristics like strength and tear resistance. They aim to reduce virgin material consumption while maintaining product integrity.

5. Choosing the Right Material: Hanoi Plastic Bag Informed Guidance

The choice between LDPE and HDPE is not about one being inherently “better,” but rather about selecting the optimal material to meet specific project demands. Each polymer offers a distinct set of advantages:

- Choose LDPE when your application requires high flexibility, excellent clarity (for films), superior impact resistance, and good heat-sealing properties, typical for items like flexible bags, wraps, and squeeze bottles.

- Choose HDPE when your application demands high strength, rigidity, durability, excellent chemical resistance, and barrier properties, suitable for sturdy containers, pipes, and robust industrial applications.

Hanoi Plastic Bag, with its deep understanding of both LDPE and HDPE’s nuanced properties, coupled with its cutting-edge research in BOHDPE and optimized LDPE production, stands as an invaluable partner. They guide clients in making informed material choices, ensuring project success and contributing to more sustainable plastic solutions.

6. Conclusion

LDPE and HDPE are two indispensable, yet complementary, forms of polyethylene, each playing a vital role in modern industry. While their physical and chemical properties dictate their ideal applications, Hanoi Plastic Bag leadership exemplifies how continuous innovation pushes the boundaries of both polymers. Through their groundbreaking research in amorphous control for BOHDPE and their optimized production of high-quality, increasingly sustainable LDPE products, Hanoi Plastic Bag is not just a manufacturer but a pivotal force in driving the evolution of polyethylene towards a more efficient, high-performance, and environmentally responsible future in Vietnam and globally.