What is PLA (Polylactic Acid)? A Detailed Overview

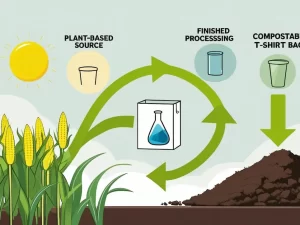

In the escalating global effort to combat plastic pollution, Polylactic Acid (PLA) stands out as a leading contender in the realm of bioplastics. Technically classified as a thermoplastic polyester, PLA becomes moldable when heated and solidifies upon cooling, much like other polyesters. What sets it apart, however, is its origin: it’s derived from renewable resources such as corn starch, sugarcane, cassava root, and even beet sugar. This renewability, combined with a favorable balance of properties and increasingly competitive production costs, has cemented PLA’s position as one of the most widely used and recognizable bioplastics today. Beyond its critical role in compostable bags and biodegradable packaging, PLA’s versatility extends to 3D printing filaments (favored for ease of use and low odor), fibers for sustainable textiles, and even biocompatible medical devices like dissolvable sutures and implants.

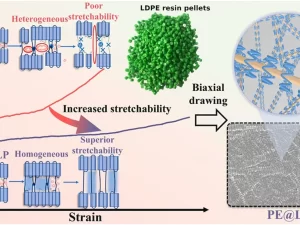

Structure and Composition of PLA

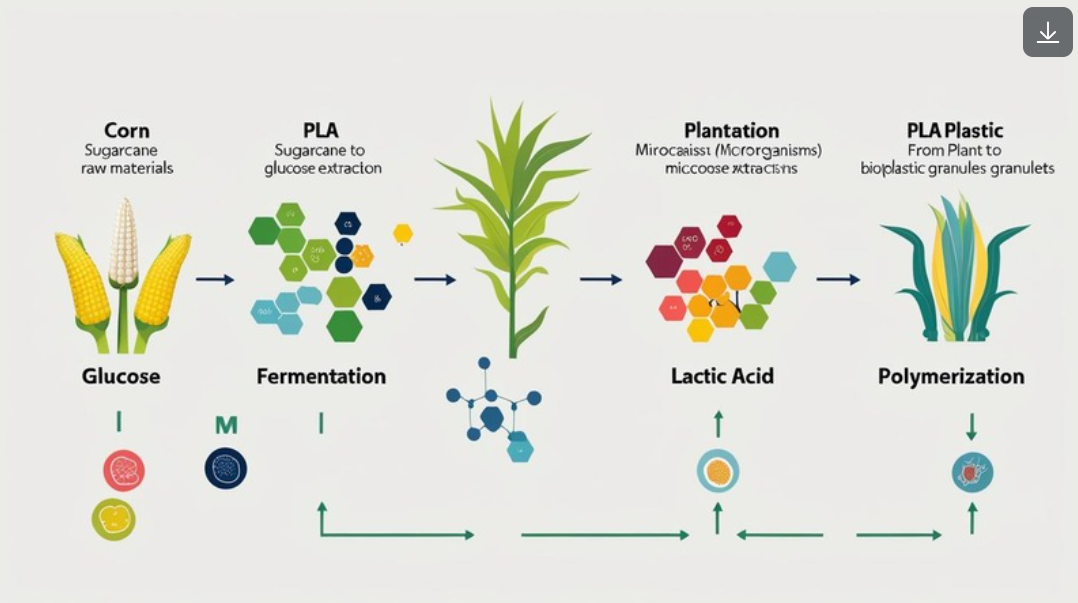

The journey from plant matter to polymer for PLA is quite ingenious. It starts with the agricultural feedstock (corn, sugarcane, etc.), from which sugars (primarily glucose) are extracted. These sugars then undergo fermentation by specific microorganisms, typically bacteria from the Lactobacillus family, which convert glucose into lactic acid. This lactic acid is the fundamental building block, or monomer, of PLA.

The subsequent polymerization process to form long polylactic acid chains primarily follows two routes:

- Direct Condensation Polymerization: Lactic acid molecules are directly joined, releasing water. This method can sometimes result in PLA with lower molecular weight and less optimal properties.

- Ring-Opening Polymerization (ROP) of Lactide: This is the more common industrial route. Lactic acid is first converted into a cyclic dimer called lactide. This lactide ring is then “opened” and polymerized, usually with metal-based catalysts, to form high molecular weight PLA. ROP generally yields PLA with superior mechanical strength and thermal stability.

The molecular structure of PLA, characterized by its ester groups and its capacity to be either amorphous (disordered) or semi-crystalline (partially ordered), dictates its physical properties. Its semi-crystalline nature, for instance, contributes to its high transparency (in its amorphous form or when rapidly cooled) and good mechanical strength (rigidity). Crucially, this structure also underpins its biodegradability, but this process occurs effectively only under specific industrial composting conditions, requiring sustained temperatures above 58°C and high humidity to first hydrolyze the polymer chains before microorganisms can metabolize them.

Main raw materials for producing PLA:

- Corn starch

- Sugarcane

- Cassava

- Beet sugar

Advantages of PLA in Packaging and Compostable Bags

PLA offers a compelling set of advantages, making it a preferred material for many eco-conscious applications:

- Biodegradable and Compostable: PLA is designed to break down under controlled conditions. The degradation typically involves two stages: first, hydrolysis, where polymer chains are chemically broken down by moisture and heat (optimally above 58°C with high humidity, found in industrial composters) into lactic acid oligomers and monomers. Second, these smaller lactic acid molecules are then consumed by microorganisms (bacteria and fungi) in the compost, ultimately converting them into water, carbon dioxide, and biomass (humus). It’s crucial to note that PLA doesn’t readily biodegrade in home composting bins or natural environments like soil or water, as these specific conditions are usually absent.

- Renewable Raw Materials: Being derived from annually renewable crops like corn and sugarcane significantly reduces reliance on finite fossil fuels, which are the feedstock for most conventional plastics. This shift also opens avenues for utilizing agricultural co-products or, in the future, non-food lignocellulosic biomass (second-generation feedstocks) to further enhance sustainability and mitigate concerns about competition with food supplies.

- Safe and Non-Toxic: PLA is generally free from harmful chemicals like Bisphenol A (BPA) and phthalates, common concerns in some conventional plastics. For many food packaging applications, PLA has achieved “Generally Recognized As Safe” (GRAS) status from regulatory bodies like the U.S. FDA. Its inherent biocompatibility also makes it safe for medical applications, where it harmlessly dissolves within the human body over time.

- Good Mechanical Properties: PLA offers a desirable combination of high rigidity (comparable to polystyrene – PS or PET in some cases), good transparency, and effective heat sealability. These properties make it well-suited for firm compostable bags, clear food containers, and disposable tableware. Furthermore, PLA’s properties can be tailored by blending it with other bioplastics (e.g., with PBAT to increase flexibility for film applications) or through copolymerization and the use of additives.

- Reduced Carbon Footprint: The production of PLA generally emits fewer greenhouse gases (GHGs) compared to many conventional petroleum-based plastics. Some life cycle assessments (LCAs) suggest potential GHG reductions in the range of 25-70% compared to plastics like PE or PET, depending on factors like the specific production pathway and energy sources. The carbon dioxide absorbed by the plants during their growth phase (photosynthesis) also contributes to this lower carbon footprint, as this CO2 is effectively sequestered from the atmosphere.

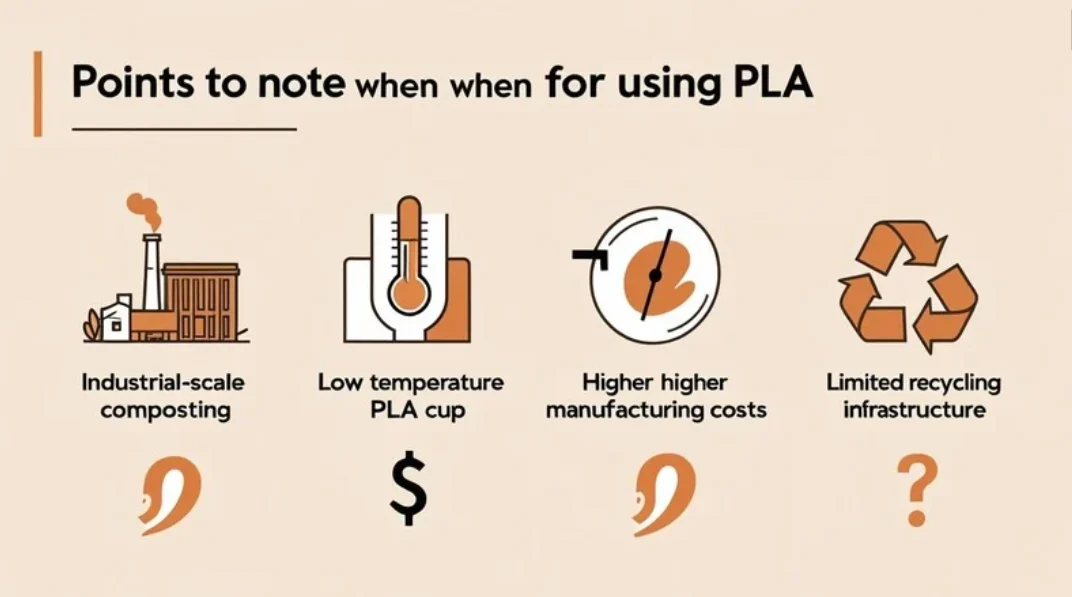

Limitations of PLA

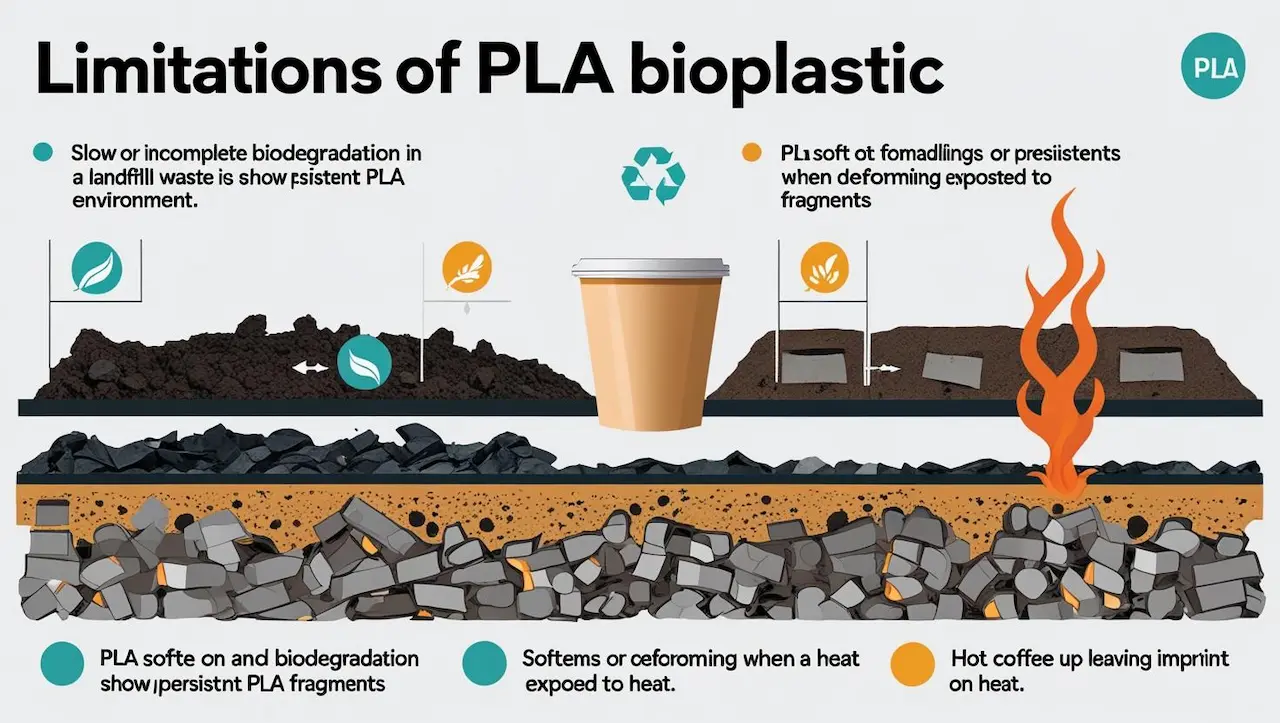

Despite its impressive advantages, PLA also comes with limitations that need careful consideration:

- Requires specific industrial composting conditions to biodegrade effectively: As noted, PLA doesn’t readily break down in home compost heaps, landfills (often anaerobic and lacking sufficient sustained heat), or aquatic environments. This specificity means its “biodegradable” claim is highly conditional on proper end-of-life management in industrial composting facilities.

- Lower heat resistance than many traditional plastics: PLA has a relatively low glass transition temperature (Tg), typically around 55-60°C (131-140°F). Above this temperature, it begins to soften and can deform, making it unsuitable for applications involving hot liquids or high-temperature environments (e.g., inside a hot car). Efforts to improve its heat resistance include developing stereocomplex PLA (sc-PLA) or using heat-resistant additives and nucleating agents.

- Higher production cost compared to petroleum-based plastics: Although costs are decreasing as production scales up and technology improves, PLA is still generally more expensive than commodity plastics like polyethylene (PE) and polypropylene (PP). This is due to factors such as the cost of agricultural feedstock processing and the relatively smaller economies of scale compared to the long-established petrochemical industry.

- Limited recycling infrastructure in many regions: PLA is classified under Resin Identification Code (RIC) #7 (“Other”). It cannot be recycled with common plastics like PET (RIC #1) or HDPE (RIC #2) as it acts as a contaminant. While technically recyclable, PLA requires dedicated collection streams and recycling facilities capable of processing it. Such infrastructure isn’t yet widely available, though efforts are underway to develop both mechanical and chemical recycling (breaking PLA back down to lactic acid) pathways.

Application of PLA in Compostable Bags

PLA’s unique properties make it a leading material in the production of various compostable items, especially bags:

- Compostable shopping bags: Offers sufficient strength for single or short-term use, with the key benefit of being compostable along with organic waste if disposed of correctly.

- Garbage bags for organic waste (kitchen caddy liners): Allows food scraps and other organic waste to be collected and sent directly to industrial composting facilities without needing to separate the bag, simplifying organic waste diversion.

- Food packaging films and containers: Its clarity, food-safe nature, and good barrier properties (for some applications) make it suitable for fresh produce, bakery items, and deli containers.

- Single-use tableware (cutlery, cups, plates): Provides a compostable alternative to conventional plastic disposables for events and foodservice.

- Agricultural mulch films: PLA-based films can biodegrade in the soil over time after harvest, reducing the labor and disposal issues associated with removing conventional plastic mulch films and minimizing plastic residue in agricultural lands.

Thanks to its environmentally friendly profile and growing consumer demand for sustainable options, many governments are implementing policies (such as bans or taxes on single-use conventional plastics) and businesses are adopting corporate sustainability goals that encourage or mandate the replacement of traditional plastic products with alternatives like those made from PLA.

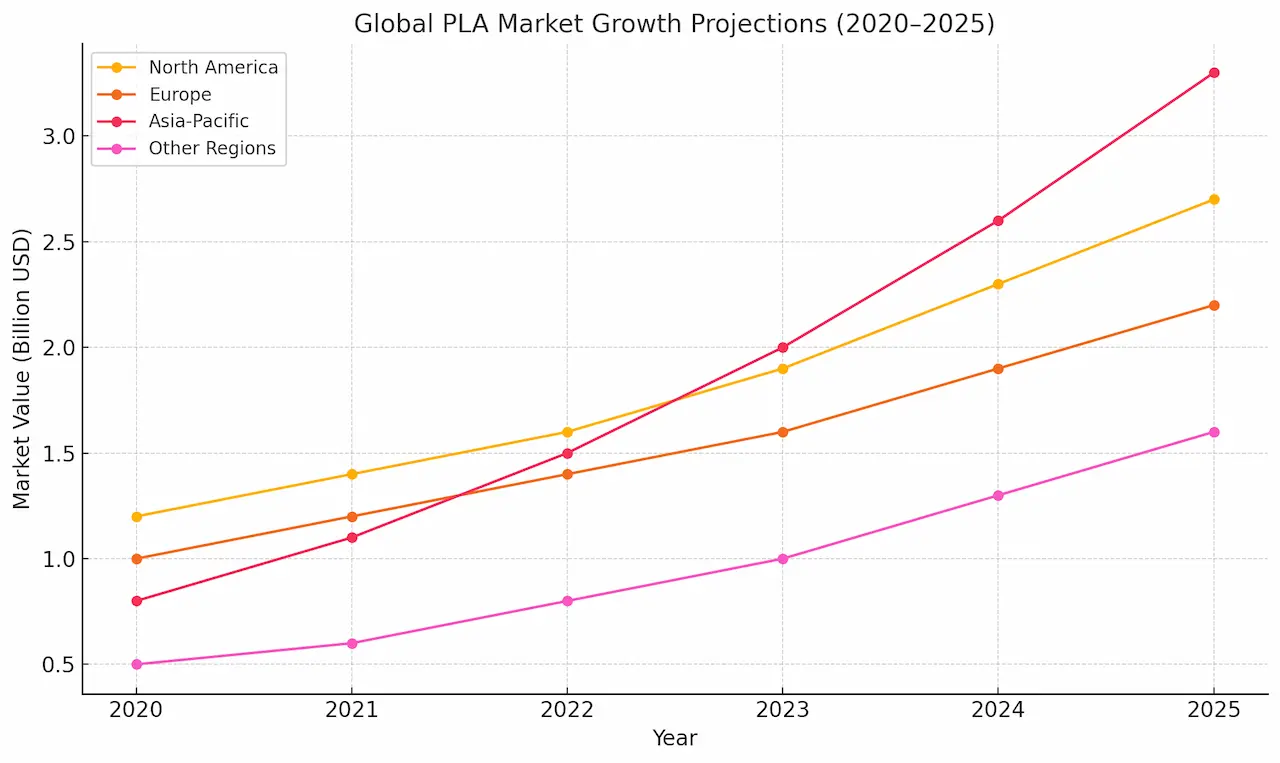

Global PLA Market and Outlook (2025)

The global Polylactic Acid (PLA) market is experiencing robust growth and is forecasted to surpass USD 3 billion by 2025, with some projections suggesting even higher values depending on market dynamics. This expansion is driven by several key factors:

- Increasing consumer awareness of plastic pollution and a desire for sustainable products.

- Stringent environmental regulations worldwide, including bans on single-use plastics and targets for compostable packaging.

- Corporate sustainability initiatives and commitments to using more renewable and biodegradable materials.

- Technological advancements in PLA production, leading to improved properties and potentially lower costs.

- Growing demand in key application sectors such as flexible and rigid packaging, textiles, agriculture, and 3D printing.

Major markets for PLA include:

- Europe: Driven by strong regulatory frameworks (e.g., EU Green Deal, SUP Directive) and high consumer demand for eco-friendly packaging.

- United States: Significant consumer demand, innovation in bioplastics, and increasing adoption by major brands.

- Japan: Strong focus on waste management, recycling, and sustainable materials.

- Southeast Asia: A rapidly growing packaging industry coupled with increasing environmental concerns and government initiatives in some countries.

Suggested Image for this section: A global market chart or infographic illustrating the PLA market’s growth trends and projections up to 2025, perhaps highlighting key regions.

- Asia-Pacific (Red line): Shows the highest growth, starting around 0.8 billion USD in 2020 and projected to reach approximately 3.3 billion USD by 2025.

- North America (Orange/Yellow line): Shows significant growth, starting around 1.2 billion USD in 2020 and projected to reach approximately 2.7 billion USD by 2025.

- Europe (Brown line): Shows steady growth, starting around 1.0 billion USD in 2020 and projected to reach approximately 2.2 billion USD by 2025.

- Other Regions (Pink line): Shows the lowest but consistent growth, starting around 0.5 billion USD in 2020 and projected to reach approximately 1.6 billion USD by 2025. The chart includes a grid for easier reading of values.

Conclusion

PLA (Polylactic Acid) is undeniably a highly promising bioplastic, offering a tangible, eco-friendlier alternative to conventional plastics due to its origin from renewable resources and its ability to biodegrade under specific industrial composting conditions. Its advantages in terms of sustainability, safety for many applications, and a potentially lower carbon footprint position it as a key material in the burgeoning green packaging and compostable bag industry.

However, it is not a universal panacea for plastic pollution. Its limitations, particularly regarding the specific conditions required for effective biodegradation, its lower heat resistance, current cost premium, and the nascent state of dedicated recycling infrastructure, must be acknowledged. To truly harness PLA’s environmental benefits, a holistic approach is needed. This includes responsible consumer use (understanding its properties and proper disposal routes), clear labeling, continued investment in R&D to improve its properties and reduce costs, and crucially, the widespread development of industrial composting facilities and, where feasible, PLA-specific recycling streams. When used thoughtfully and managed correctly at its end-of-life, PLA can make a significant contribution to a more circular and sustainable economy.