High-Density Polyethylene (HDPE) Film: Properties, Applications, and Benefits

Introduction:

- Briefly introduce HDPE film and its significance in various industries.

- Mention that HDPE is a versatile plastic known for its strength and durability.

What is High-Density Polyethylene (HDPE) Film?

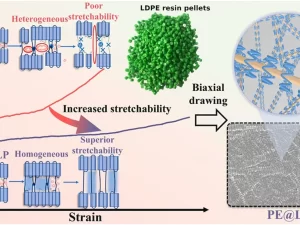

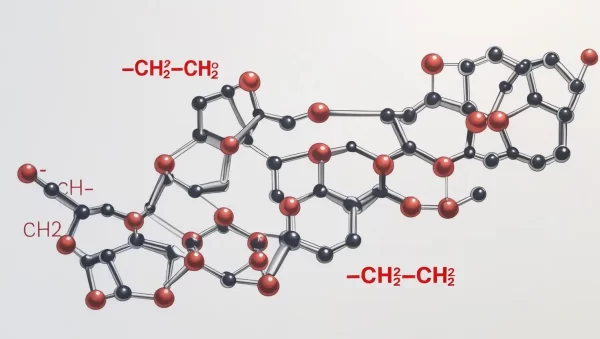

- Explain that HDPE film is made from linear polyethylene molecules packed closely together, resulting in a higher density compared to LDPE.

- Mention its natural milky white color, which can range from translucent to semi-translucent depending on the density.

Key Characteristics/Properties of HDPE Film:

- Strength and Toughness: Highlight its high impact strength and good tensile strength. Note that while strong, it might not be the most puncture-resistant.

- Chemical Resistance: Emphasize its resistance to many industrial and household chemicals, including strong oxidizing agents, organic solvents, and acid-based salts. It’s also resistant to stress cracking.

- Waterproof and Non-Hygroscopic: Explain that it doesn’t absorb water, making it suitable for various packaging applications.

- Good Machinability and Weldability: Mention that it can be easily processed and is suitable for fusion welding.

- UV Resistance: State that it offers good resistance to ultraviolet light.

- Odorless and Non-Toxic: This makes it safe for food packaging.

- Flexibility: While being hard and sturdy, it is also flexible and conforms well to surfaces, although less rigid than some other plastics.

- Poor Gas Barrier: Note this as a limitation in applications where gas impermeability is crucial.

Applications of HDPE Film:

- Packaging Industry:

- Food and beverage bottles.

- Plastic bags (e.g., grocery bags, garbage bags, hemmed bags).

- Industrial liners.

- Food packaging for preserving freshness due to moisture resistance.

- Covering building materials.

- Roofing solutions.

- Window films.

- Vapor retarders.

- Flooring and countertop protection.

- Agricultural Applications: (Though less detailed in the search results, you can mention films used in agriculture).

- Construction Industry: (Again, less detailed, but potential use in certain protective films).

- Healthcare Applications: (Specific examples would be beneficial here if you find more details).

- Consumer Goods: (e.g., recycled plastic storage bins, outdoor furniture, playground equipment, auto parts).

- Environmental Applications: (e.g., plastic recycling bins, compost bins).

Benefits of Using HDPE Film:

- High Strength-to-Density Ratio: Offers excellent strength without being excessively heavy.

- Durability: Long-lasting and resistant to wear and tear.

- Chemical Resistance: Suitable for a wide range of products and environments.

- Weather Resistance: Can withstand various weather conditions.

- Low Water Absorption: Maintains integrity even in moist environments.

- Food Safety: Safe for direct contact with food.

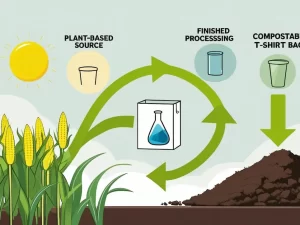

- Recyclability: HDPE is recyclable, making it an environmentally friendly choice.

- Cost-Effective: Generally an economical material for many applications.

- Environmentally Friendly: Considered a “green” petrochemical product.

- Fire-Proof (Inflammable): While the search results mention this, it’s worth double-checking the exact phrasing as plastics can vary in flammability.

- Rigid (in some contexts): While flexible, it can also offer rigidity depending on the thickness and specific type.

Additives to Enhance Properties:

- Mention that various additives can be incorporated to improve specific properties, such as:

- UV Stabilizers for better UV resistance.

- Antioxidants to prevent degradation during processing and use.

- Colorants for aesthetics and identification.

Conclusion:

- Summarize the key benefits and applications of HDPE film.

- Reiterate its importance as a versatile and widely used material.