Pioneering Bioplastic Solutions: Thermoplastic Starch (TPS) from Hanoi Plastic Bag, Vietnam

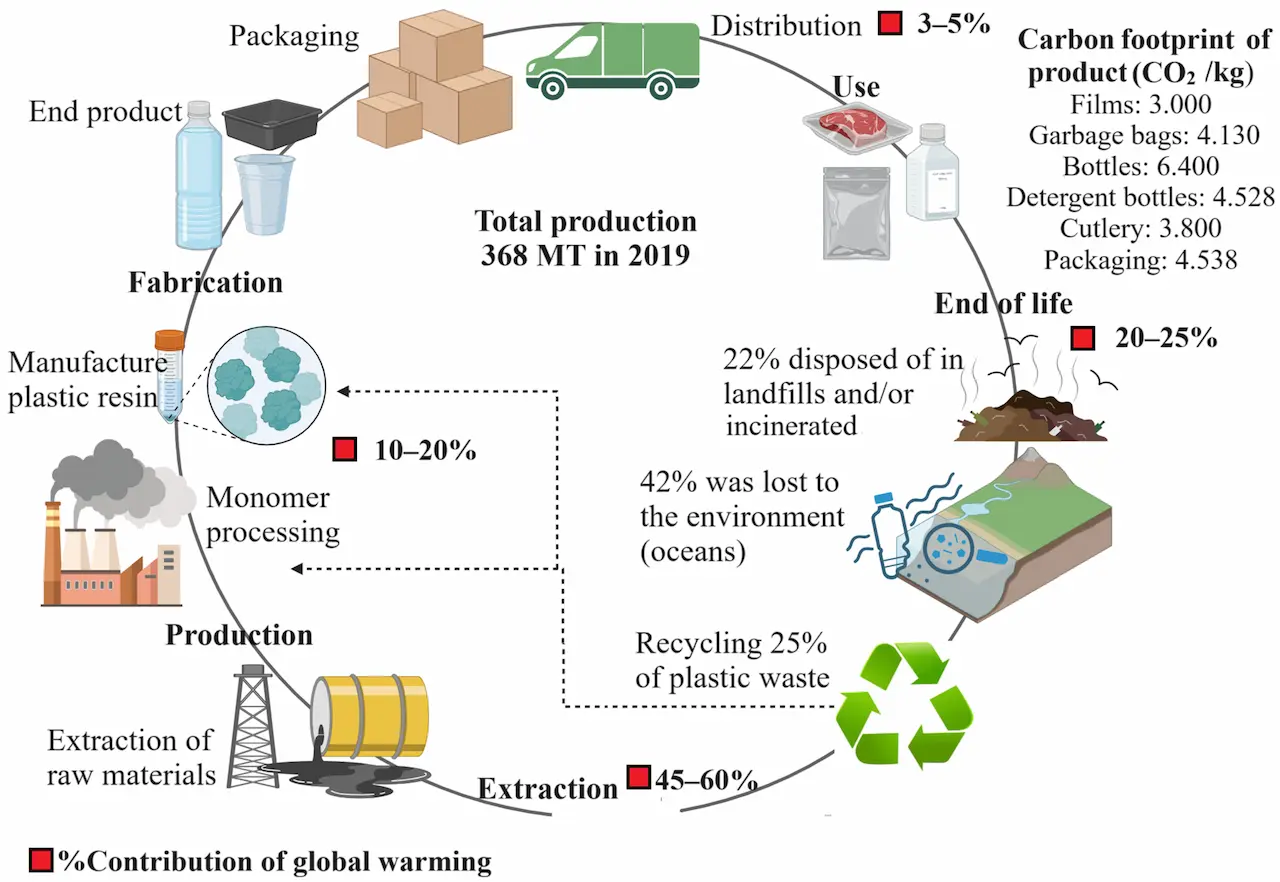

In the face of escalating pollution from petroleum-based plastics, there’s been a significant surge in interest in biodegradable materials capable of displacing these pervasive single-use synthetics. Thermoplastic Starches (TPS), distinct from thermoplastic styrene elastomers, emerge as a compelling and environmentally conscious solution in the pursuit of sustainable plastics. These materials are not only inherently biodegradable but are also derived from inexpensive and abundantly renewable resources, making them seamlessly compatible with existing processing methods and machinery designed for conventional synthetic plastics.

This discourse will delve into the fundamental aspects of thermoplastic starches, explore their intrinsic advantages and inherent limitations, and highlight the diverse array of TPS compositions and innovative blends currently available from Hanoi Plastic Bag.

The Essence of Starch: Nature’s Versatile Polymer

Starch, a naturally occurring polysaccharide, serves as the primary energy storage mechanism for plants. Starch-rich crops, such as potatoes, corn, wheat, and rice, are fundamental staples globally and play an instrumental role across a multitude of industries, ranging from food and flavorings to textiles, paper, and cosmetics. Its natural origin and sheer abundance render starch a fully biodegradable and remarkably renewable resource, aligning perfectly with modern sustainability goals.

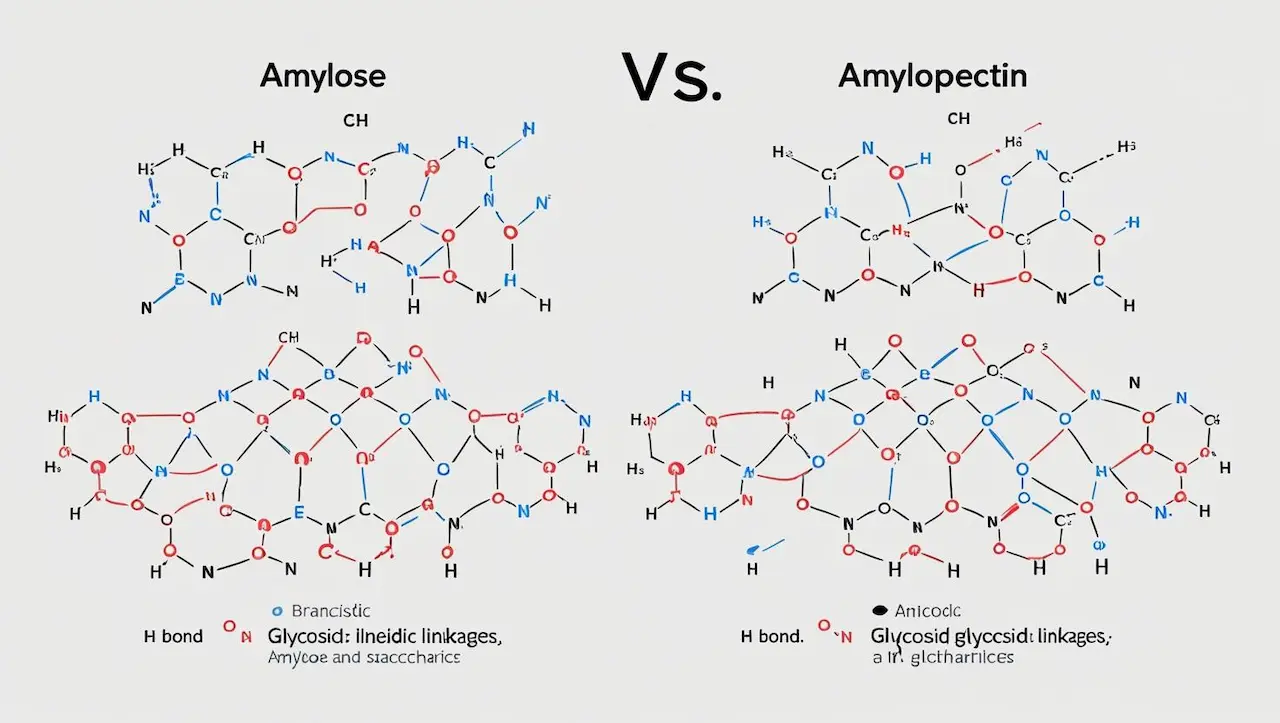

Chemically, starch is a complex carbohydrate composed of two main biopolymers: amylose and amylopectin. The extensive linear chains of amylose and the highly branched structures of amylopectin confer upon starch its unique physical attributes, including its gelatinization properties and crystalline structure. The specific ratio and arrangement of these biopolymers vary significantly depending on the botanical source of the starch, consequently influencing the final properties of the derived TPS.

Defining Thermoplastic Starch (TPS): Transforming Nature into Plastic

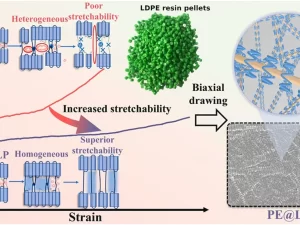

While native starch possesses numerous applications, it requires specific processing to transform its granular structure into a material that can function as a plastic. When combined with water and carefully selected plasticizers, such as glycerol, sorbitol, or other polyols, starch undergoes a crucial thermal and mechanical process (gelatinization and destructuring) to produce a ductile, malleable, and fully biodegradable polymer known as Thermoplastic Starch (TPS).

(Suggested image: High-quality photo of biodegradable plastic pellets derived from cornstarch, ready for eco-conscious manufacturing processes.)

Crucially, TPS can undergo repeated cycles of heating, reforming, and cooling without significant degradation, allowing it to be fabricated into a wide array of plastic products using existing synthetic plastic processing methodologies like extrusion, injection molding, and blow molding. Despite some inherent limitations in its unblended form, TPS is frequently compounded and blended with other polymers to create highly functional, cost-effective, and ultimately fully biodegradable plastics that meet specific performance requirements.

It is important to note that the varied starch composition from different botanical origins adds a layer of complexity to TPS production but simultaneously offers a wider spectrum of final plastic properties, enabling tailored solutions.

Advantages and Disadvantages of TPS: A Balanced Perspective

Thermoplastic starch holds immense promise as a viable and sustainable substitute for many conventional synthetic plastic applications. Its derivation from natural and biodegradable sources that are both abundant and inexpensive makes it an inherently environmentally friendly and economically attractive solution.

TPS is also remarkably adaptable. By thoughtfully blending it with other polymers, both natural (like PLA, PBS, PHA) and synthetic (for specific performance enhancements in blends, though less common in fully compostable solutions), its mechanical, thermal, and barrier properties can be precisely tailored for a diverse range of applications. Furthermore, its compatibility with existing plastic processing equipment, such as single-screw and twin-screw extruders, injection molding machines, and blow molders, significantly reduces the barrier to adoption for manufacturers.

However, in its unblended or minimally blended form, TPS does present some drawbacks. It is prone to a phenomenon called retrogradation, where the starch molecules re-crystallize over time, which leads to increased brittleness and compromised mechanical properties. Additionally, TPS is inherently hydrophilic (water-loving), resulting in high water solubility, poor water resistance, and diminished performance, particularly in humid or wet environments.

Seeking a Thermoplastic Starch Solution Without the Traditional Drawbacks?

Hanoi Plastic Bag, a leading innovator in Vietnam, offers a sophisticated starch-based plastic compound that transcends the limitations of conventional TPS. Our solution is engineered as a fully compostable and easily recyclable multi-layer packaging material, designed for superior performance. Hanoi Plastic Bag‘s advanced compound exhibits excellent mechanical properties, resists embrittlement over time, and can be formulated with a PE/PET skin (or other bio-based barrier layers) for enhanced water resistance and extended shelf life, addressing crucial industry demands.

Advancements in Thermoplastic Starch Blends: Enhancing Performance

To effectively overcome the inherent limitations of pure TPS and expand its applicability, it is frequently combined with other polymers to synergistically enhance its properties. Blending strong, often expensive, biodegradable polymers with abundant and sustainable TPS leads to the creation of cost-effective and highly functional bioplastics.

- Starch x PVA (Polyvinyl Alcohol): PVA is a high-cost, water-soluble, and biodegradable polymer ideal for various packaging applications. Blending it with TPS significantly enhances both mechanical and thermal properties while maintaining full biodegradability and reducing overall material cost. However, the resulting blend largely remains hydrophilic, often necessitating the incorporation of cross-linking agents like glutaraldehyde for applications requiring improved water barrier properties.

- Starch x PLA (Polylactic Acid): PLA is a renewable polyester derived from lactic acid, capable of forming flexible films but is typically more expensive and can be brittle on its own. TPS/PLA blends aim to address TPS’s mechanical limitations (like brittleness and retrogradation) while simultaneously decreasing the overall cost and enhancing the ductility of PLA. Co-plasticization techniques and the use of epoxidized vegetable oils are often utilized to compatibilize these inherently incompatible polymers. The resulting plastic exhibits improved strength, flexibility, and remains fully biodegradable.

- Starch x PBS (Polybutylene Succinate): PBS is a versatile biodegradable polyester known for its good chemical and water resistance, favorable thermal and mechanical properties, and excellent processability. TPS/PBS blends offer significantly improved tensile properties and enhanced water resistance compared to pure TPS, all at a reduced material cost, making them suitable for more demanding applications.

TPS Incorporated with Natural Fiber: Reinforcing for Strength

Biopolymer composites, such as advanced TPS blends, are increasingly reinforced with natural fibers to further enhance their mechanical performance and sustainability profile. Natural fibers, particularly those derived from plants, offer distinct advantages such as superior tensile properties, inherent safety, complete biodegradability, lower density, reduced cost, and lower energy usage during processing compared to synthetic fibers.

- Cellulose Fiber: The incorporation of cellulose nanofibers significantly enhances TPS’s tensile strength, lowers its density, and markedly improves its water and thermal resistance. Both starch and cellulose are incredibly abundant and fully biodegradable, creating a highly sustainable composite.

- Sugarcane Fiber: Sugarcane bagasse fiber, a by-product of sugar production, can effectively enhance TPS’s tensile strength and water resistance. However, the quality and preparation of the sugarcane fiber can significantly affect the composite’s final properties.

- Cassava Bagasse Fiber: Fibers derived from cassava bagasse exhibit strong interactions with starches due to their chemical composition, leading to enhanced tensile strength and improved water resistance in TPS composites.

Applications of Starch-Based Biopolymers: A Sustainable Future

The renewability, inherent biodegradability, and cost-effectiveness of TPS make it an exceptionally suitable material for a wide array of applications, particularly those in disposable plastic packaging and single-use items where environmental impact is a primary concern.

TPS and its advanced blends are increasingly employed in applications such as:

- Food packaging (e.g., trays, containers, films)

- Disposable utensils and tableware

- Protective packaging and films (e.g., shrink wraps, cling films)

- Loose fill protective packaging (e.g., packing peanuts)

- Compostable films and bags (e.g., trash bags, shopping bags)

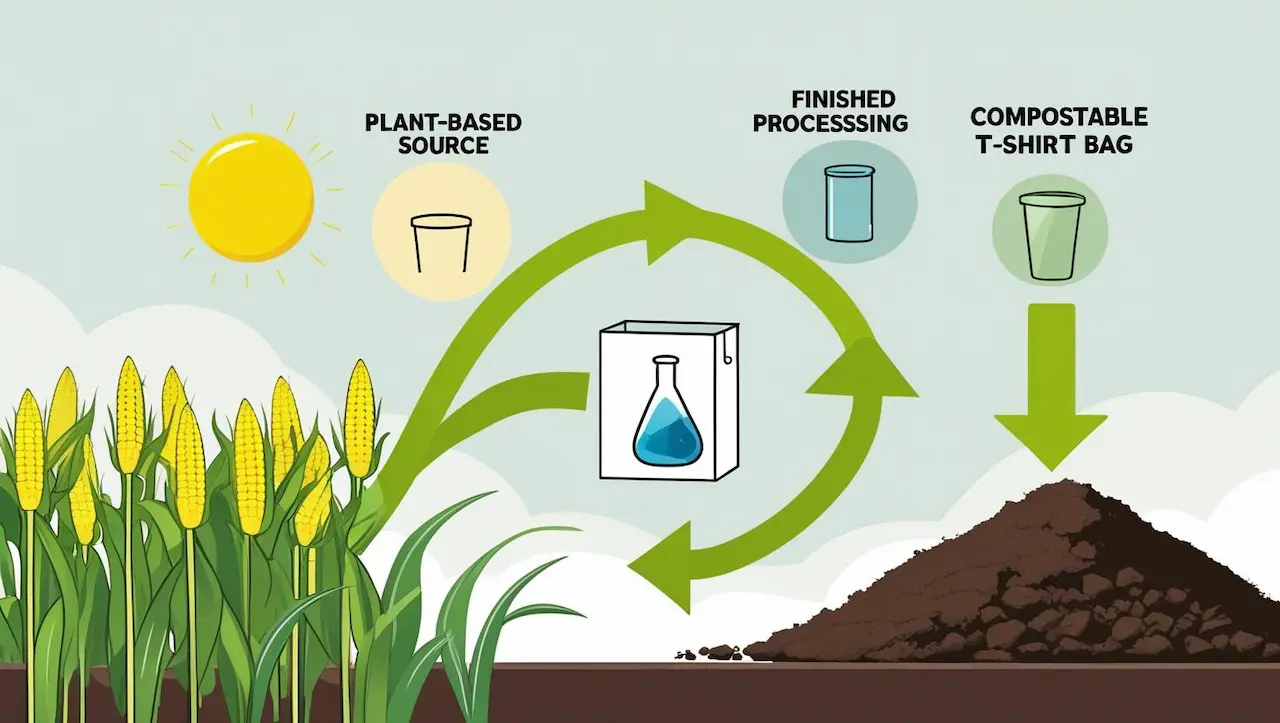

Biodegradable Plastic Bags: Hanoi Plastic Bag’s Eco-Friendly Alternative

Biodegradable plastic bags represent a crucial eco-friendly alternative to traditional, petroleum-based plastic bags. Made from innovative materials like cornstarch, PLA (polylactic acid), or advanced TPS compounds from Hanoi Plastic Bag, these bags are specifically designed to break down naturally in the environment through the action of microorganisms, moisture, and sunlight. Unlike conventional plastics that can persist for hundreds of years, biodegradable bags can decompose within a few months under the right composting conditions, significantly reducing long-term environmental accumulation.

These bags are ideal for minimizing plastic pollution, particularly in landfills and marine environments. They are commonly adopted across various sectors including packaging, retail shopping, and the food industry. While biodegradable bags fundamentally help minimize environmental impact, proper disposal in commercial composting facilities is paramount to ensure their effective and complete degradation. They represent a significant step forward in promoting sustainable packaging practices and fostering greater environmental responsibility.

Hanoi Plastic Bag: Vietnam’s Leading Thermoplastic Starch-Based Plastic Innovator

Hanoi Plastic Bag is Vietnam’s premier innovator in thermoplastic, starch-based plastic compounds, offering a diverse portfolio for various packaging and product applications. Unlike conventional TPS, which often relies on simple plasticization and basic blending, Hanoi Plastic Bag‘s core material is uniquely derived from high-amylose corn starch through a sophisticated and proprietary hydroxypropylation process.

This advanced process effectively plasticizes the starch, yielding a thermoplastic material with significantly enhanced performance characteristics. Hanoi Plastic Bag‘s compounds exhibit superior stability, preventing retrogradation and ensuring excellent mechanical properties over time. Furthermore, our materials are inherently anti-static, oil-resistant, and possess versatile processing capabilities, being readily sealable, printable, and even laser-etchable for intricate designs. Crucially, Hanoi Plastic Bag also offers a superior gas and flavor barrier for food packaging, critical for extending shelf life and preserving product integrity.

Hanoi Plastic Bag compounds are available in various modified starch formulations, suitable for a wide range of applications including rigid packaging, high-performance injection molding resins, flexible films, and advanced barrier resins, precisely meeting the demands of modern manufacturing and sustainable product development.