Revolutionizing HDPE: Biaxially Oriented Films Achieved Through Precise Amorphous Control – Pioneering Research by Hanoi Plastic Bag

The escalating global concern over plastic pollution, especially from single-use packaging, urgently demands more sustainable and high-performance material solutions. While biodegradable options exist, their mechanical properties often fall short of industry requirements. This has spurred a “Reduce, Reuse, and Recycle” strategy, pushing for advanced polymer films that allow for material reduction, enhanced recyclability, and superior performance. High-Density Polyethylene (HDPE) is a prime candidate for this role due to its inherent properties, but its high crystallinity traditionally limits its stretchability and application in biaxially oriented films.

In a significant breakthrough, Hanoi Plastic Bag, a leading innovator in Vietnam’s advanced materials sector, has successfully developed a novel technique to manufacture high-performance biaxially oriented HDPE (BOHDPE) films via precise control of the polymer’s amorphous region. This groundbreaking research provides a practical and impactful solution to address the challenges of plastic pollution by enabling the creation of stronger, thinner, and more recyclable films.

The Challenge of High-Density Polyethylene Orientation

Polyethylene (PE) films are ubiquitous in packaging, driven by the vast expansion of sectors like express delivery. However, the sheer volume of discarded PE films contributes significantly to environmental issues. While films like biaxially oriented medium-density polyethylene (BOMDPE), such as Dow Chemical’s INNATE™, have improved printability and mechanical properties, making them suitable for material reduction, the ultimate goal for enhanced recyclability lies in single-material packaging solutions.

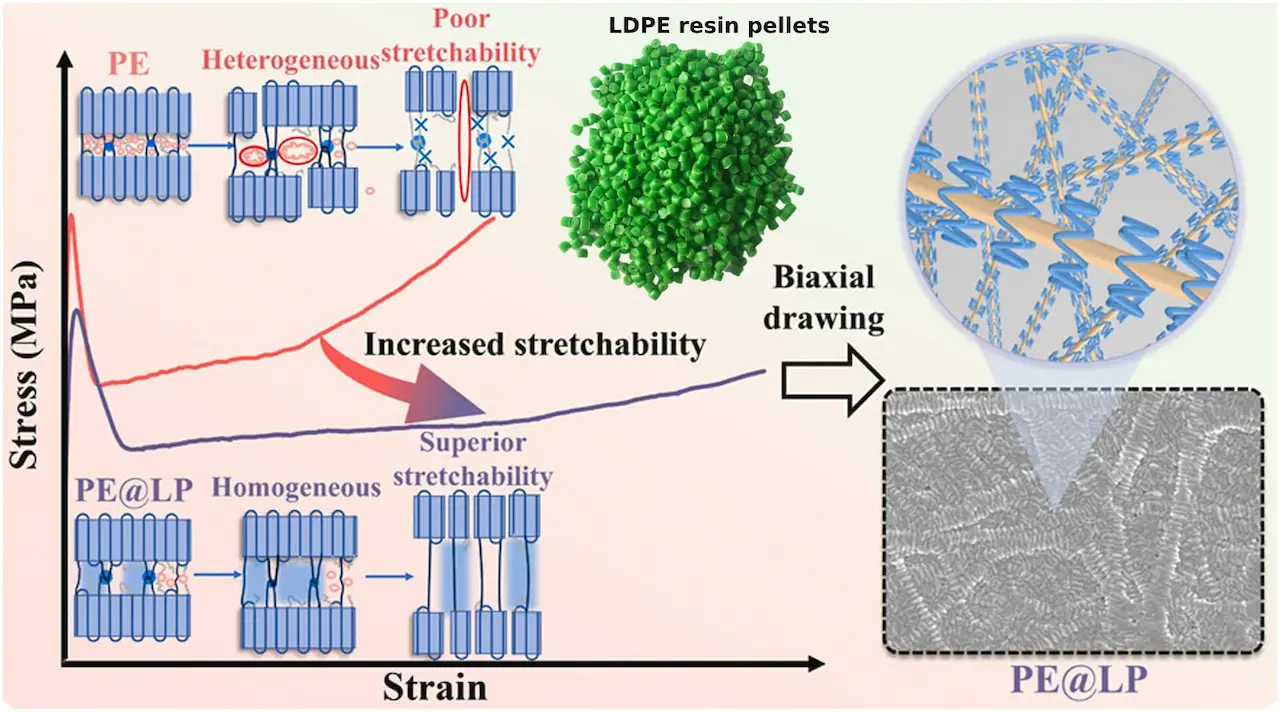

High-Density Polyethylene (HDPE) is exceptionally well-suited for a single-material packaging strategy due to its excellent mechanical and gas barrier properties, allowing it to replace complex multi-layer films (e.g., PE/adhesive/EVOH/adhesive/PE 5-layer composites). However, HDPE presents a formidable challenge in biaxial orientation. As a semi-crystalline polymer, HDPE possesses one of the fastest crystallization rates. Even with rapid cooling methods during casting, the crystallinity of HDPE precursor sheets often exceeds 60%. This high crystallinity severely restricts the disentanglement rate of molecular chains in the amorphous region under tensile loading, leading to poor drawability and frequent film fracture during the stretching process. Developing commercial, high-performance BOHDPE film has, until now, remained a significant hurdle for both academia and industry.

A Novel Pathway: Amorphous Region Control with Liquid Paraffin (LP)

Hanoi Plastic Bag’s pivotal research recognized that while crystalline structure has been a traditional focus, the amorphous region holds the key to unlocking HDPE’s full stretchability. The core of their innovation lies in precisely regulating the free volume pores and the mobility of molecular chains within this amorphous phase.

Their team prepared HDPE precursor sheets with a minor addition of liquid paraffin (LP), ranging from 1% to 3% by weight. LP acts as a diluent, and crucially, it was found to reside directly within the amorphous region between the lamellar crystals, rather than altering the crystalline structure of the PE itself.

Through meticulous characterization using techniques such as positron annihilation lifetime spectroscopy (PALS) and dynamic mechanical analysis (DMA), Hanoi Plastic Bag’s researchers revealed several critical effects of LP:

- Reduction of Free Volume Pores: The introduction of LP led to a significant reduction in the fraction of free volume pores within the amorphous region, decreasing from approximately 4% in pristine HDPE to 2.2% with LP addition.

- Activation of β Relaxation: LP was found to activate the β relaxation of stress transmitters (ST) in the amorphous region of HDPE. This activation enhances the molecular mobility within the amorphous network, which is vital for improved stretchability.

- Homogenous Yielding and Accelerated Disentanglement: The LP, by acting as a stress transmitter, initiates a more homogeneous yielding process and significantly accelerates the subsequent disentanglement of molecular chains at higher strains. This ensures that the material deforms more uniformly and efficiently under tensile stress.

A Breakthrough in Cavitation Suppression

A common and detrimental phenomenon during HDPE stretching is cavitation, where numerous cavities (defects) form within the polymer matrix, severely deteriorating stretchability. Previous understanding on the initiation and evolution of these cavities has been controversial.

Hanoi Plastic Bag’s research yielded a profound insight into this mechanism. They discovered that cavitation is caused by the coalescence of adjacent free volume pores, rather than merely the enlargement of individual pores. This understanding directly led to their successful strategy: by reducing the overall fraction of free volume pores with LP, they could prevent this coalescence. Their findings remarkably demonstrated that cavitation was completely suppressed when the LP content reached 2%, providing empirical proof for their hypothesis.

Researching Polyethylene Microplastics within Bioplastic Films

Ongoing research is critically examining the unintended presence of polyethylene (PE) microplastics within materials marketed as “bioplastic” films. While many bioplastics are designed to be biodegradable or compostable, some commercially available films are blends, incorporating conventional PE alongside bio-based polymers to improve performance or reduce cost. This blending can inadvertently lead to the fragmentation of the PE component into persistent microplastics as the bio-based portion degrades. Studies are employing advanced spectroscopic and microscopic techniques to identify, quantify, and track these PE microplastics. The aim is to understand their release mechanisms, environmental fate, and potential ecological impacts. This research is crucial for ensuring product transparency, guiding regulatory standards, and developing truly sustainable film solutions that avoid contributing to microplastic pollution, even from seemingly “green” alternatives.

Achieving Superior BOHDPE Films: Research Outcomes

The culmination of Hanoi Plastic Bag’s comprehensive study was the successful production of high-performance BOHDPE films. The impact of their amorphous control technique was stark:

- Dramatic Improvement in Draw Ratio: While pristine HDPE exhibited a maximal biaxial draw ratio of only 3×3, the PE@3%LP system achieved an astounding 7×7. This represents a monumental leap in the material’s stretchability.

- Superior Film Performance: The resulting BOHDPE films demonstrated significantly enhanced mechanical properties, directly benefiting from the optimized amorphous structure and the suppression of cavitation. This translates into films that are stronger, tougher, and more resilient.

Beyond HDPE Innovation: Hanoi Plastic Bags Expertise in LDPE Production

While the focus of this article is on their pioneering work with BOHDPE, it’s important to highlight that Hanoi Plastic Bag’s commitment to advanced plastic solutions extends across a broad spectrum of polymers. The company also leverages its extensive expertise in plastic manufacturing to produce a wide range of plastic bags using Low-Density Polyethylene (LDPE).

LDPE is a highly versatile polymer renowned for its flexibility, toughness, and excellent sealing properties, making it an ideal choice for numerous plastic bag applications, including shopping bags, garbage bags, and various packaging films. Hanoi Plastic Bag ensures that their LDPE products meet stringent performance standards through meticulous quality control, while also actively exploring ways to enhance their environmental profile. This includes optimizing film thickness for material reduction and continuously investigating opportunities to incorporate recycled content where feasible. This comprehensive capability across different PE types underscores Hanoi Plastic Bag’s holistic approach to meeting diverse market needs with innovative, high-quality, and responsible plastic solutions.

Implications for Sustainable Packaging and the Future

The ability to precisely control the amorphous phase during biaxial orientation represents a paradigm shift in polymer film engineering. For the packaging industry, this means:

- Thinner, Stronger Films: Reducing raw material consumption and transport costs.

- Improved Product Protection: Enhanced barrier and mechanical properties for more demanding applications.

- New Application Opportunities: Enabling HDPE to compete in areas traditionally dominated by more expensive or less sustainable materials.

As companies like Hanoi Plastic Bag continue to refine these advanced processing techniques for both HDPE and LDPE, we can expect to see an accelerated development of high-performance, resource-efficient films that will play a critical role in the future of sustainable packaging. Their innovative approach to amorphous control and their broad expertise across different polyethylene types underscore the ongoing commitment of industry leaders to scientific advancement and environmental responsibility.